12 * Diamond Polishing Pads

1 * Wool Felt Buffing Pad

1 * 5/8’’-11 Backer Pad

1 * Drill Adapter

–

Grit includes: #50, #100, #150, #300, #500, #800, #1000, #1500, #2000, #3000, #5000, #8000

Notice: The color of the back is not constant!

You can do it yourself, why hire worker to spend more?

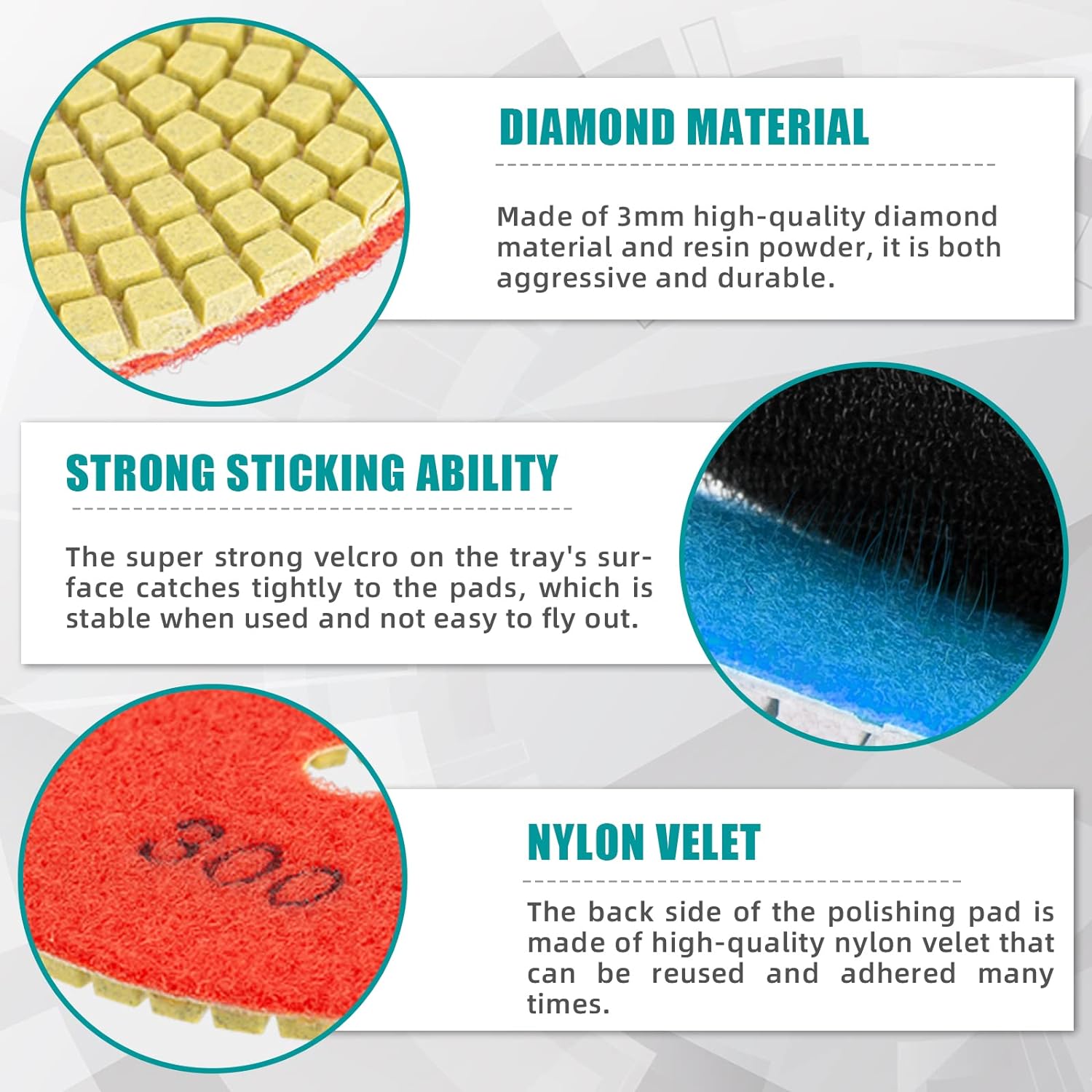

You need a high quality diamond pad; one that has perfected the bond by the mix of diamond and resins.

Choosing the correct diamond polishing pad is very important when it comes to your application. Whether it is for stone fabrication of granite, marble or other natural stone or concrete restoration, GRAUERHUND has you covered.

Unlike soft, thin pads, these are tough and durable; they do not curl and wear unevenly.

Numerous, wide grooves channel slurry out from under the disc, reducing clogging, premature pad wear and scratches from the cuttings.

Tightly graded, premium industrial diamonds cut fast but leave a smooth, scratch free surface.

Take Your Time, Go Slow and In Stages

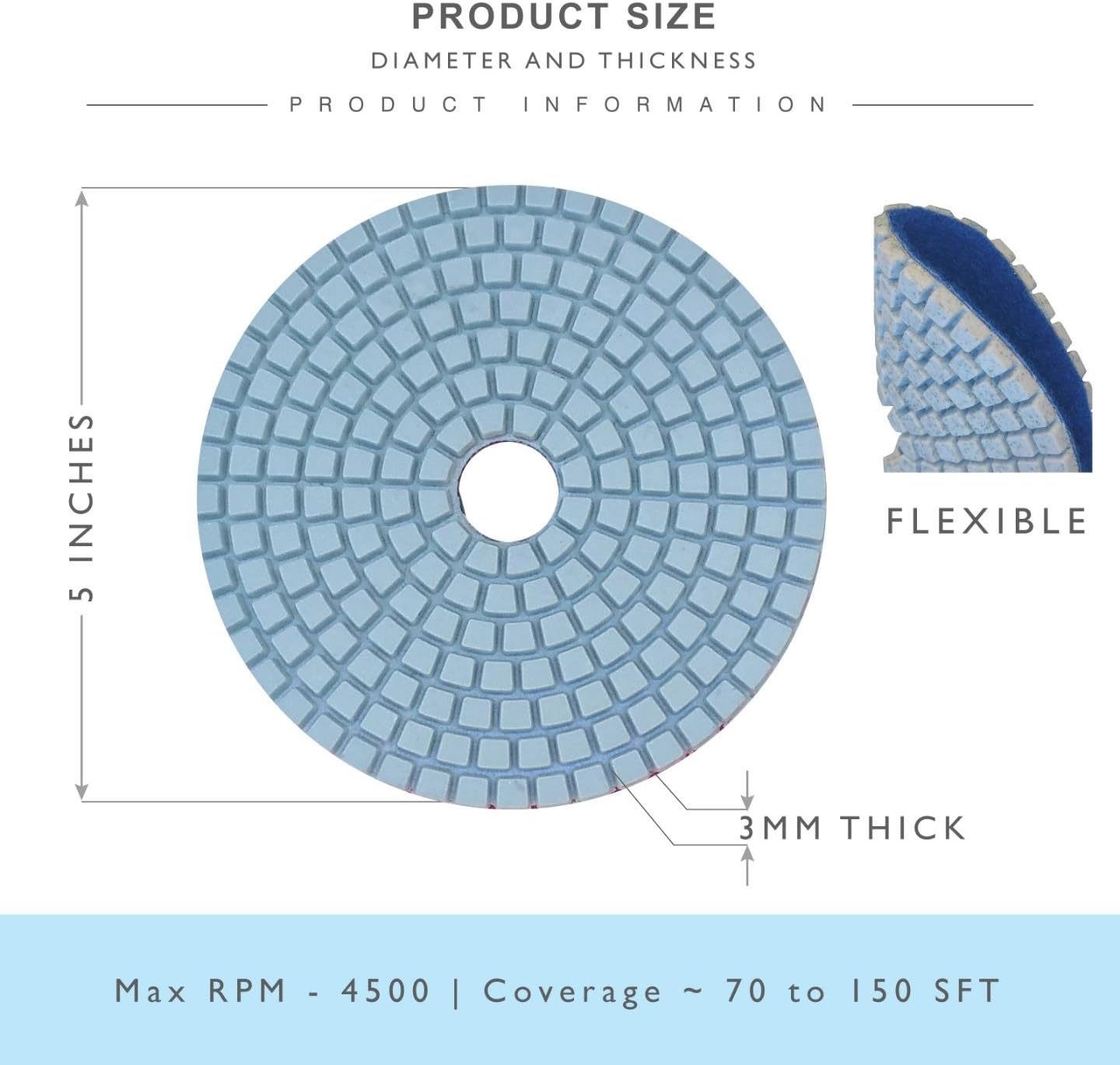

The granite diamond polishing pads are made of high-quality diamond and resin. Fast grinding force, good flexibility, wear resistance, high polishing efficiency, and long service life. The flexible diamond polishing discs are designed for wet and dry polishing, less dust, improve gloss finish in a short time.

50-150 grit suit for wet or dry polish; 300-8000 grit must be used with water to ensure the best polishing results.

-First, choose 50-150 grit polishing pad, the RPM should not be too high, can be dry polishing or wet polishing.

-Then choose 300-8000 grit polishing pad (most polishing projects don‘t need such a high grit), speed up the RPM, add water for polishing.

-Finally polish with a wool felt pad, you can add polishing paste.

-You will get a mirror finish after all the work.

Thick enough for long life.

Ideal resin binder for

Reviews

There are no reviews yet.